When you call, you can discuss your application in confidentiality with an engineer with years of experience. We recognize that not everyone is a trained thermoelectric expert, or perhaps even well versed in thermal matters. We don’t just ask how much heat you need to remove and make recommendations for that thermal load, we take the time to understand the end objective, quantify the cooling requirement, and then offer system-level suggestions for the best way to achieve that objective.

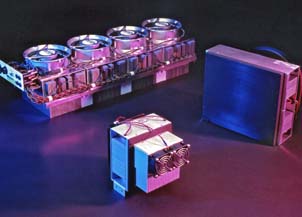

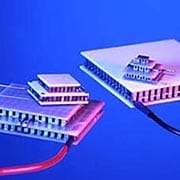

TE Technology was founded in 1989 and manufactures our cooling assemblies at our facility in Traverse City, Michigan. We are ISO 9001 registered, ITAR registered, and our data systems meet the requirements of DFAR 252.204-7012 / NIST 800-171 for our customers in the defense industry. We have an in-house machine shop, which keeps manufacturing under our control. We have our own heat sink extrusion tooling for making heat sinks optimized for demanding thermoelectric applications while minimizing assembly time and expense. TE Technology also designs and manufactures its own thermoelectric test equipment for device testing at the material, module, and assembly levels. This equipment and our tested procedures ensure quality and let you harness our infrastructure, saving you time and money.